Recently we made big changes to the workshop to reach international standard, to improve battery quality and production ability, details as below.

A.First floor upgraded <>

1,Production workshops

Imperfection: Positive and negative materials are put together, face a danger of cross-infection.

Upgraded: On the left of corridor are nagative produce precess workshops;one the right side are positive workshops. Every procedures are sperated.

Upgraded: Build a Air shower door at entrance, to aviod dust into workshop.

Upgraded: Add a first floor layout plan,to show wrokshops & procedures directly.

2, Materials Blending workshop upgraded

Previous:

1-No dust purifiers .

2-Nagative &positive materials are blending at same workshop.

Now:

1-Had install dust purifiers in workshops,dust control standard under thirty thousands level.

2-Nagative &positive materials blending are parted.

3-Windows gap had sealed,cann't open never.

Positive material blending workshop

Nagative materials blending workshop

3.Coating workshop upgraded

Previous:

1-No dust purifiers .

2-Nagative &positive materials are coating at same workshop.

Upgraded:

1-Had install dust purifiers in workshops,dust control standard under thirty thousands level.

2-Nagative &positive materials blending are parted.

Upgraded: Positive & nagative coating charging materials automatic.

Upgraded:

1,Positive materials coating workshop

2,Nagative materials coating workshop

4, Rolling compaction & Cutting workshop upgraded

Upgraded:

1-Had install dust purifiers.

2-Positive&nagative cutting workshop had parted

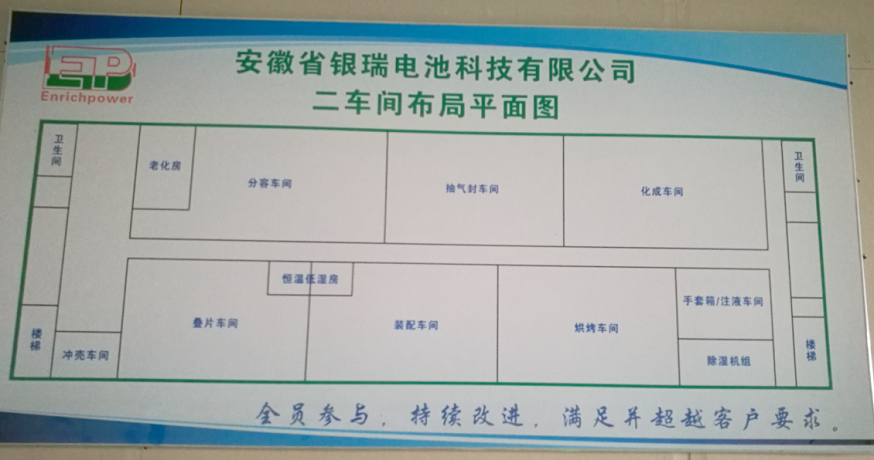

B.2nd floor workshops<>

1, Assembly & Quality test workshops

Previous:

Some workshops were didn’t seal ,result to temperture cannot be effectively controlled.

Upgraded:

1-Left of corridor are assembly workshops, right side are quality test workshops. Rational distribution to improve work efficiency.

2-All workshops are sealed.

2, 2nd floor layout plan

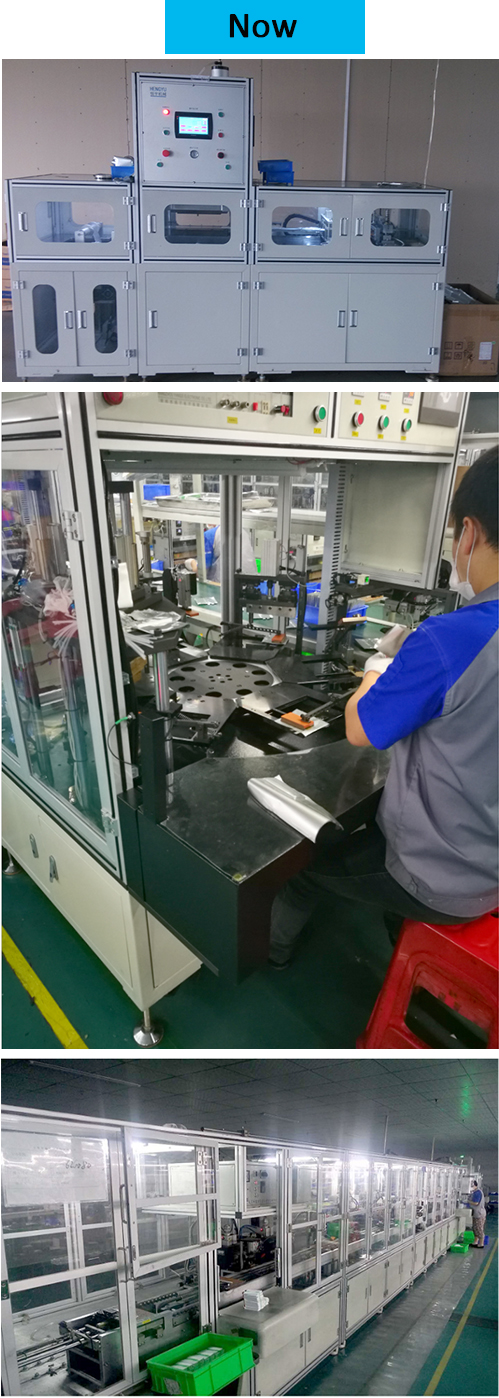

3, Stacking procedure

Previous:

1-No dust purifiers .

2-Some models Stacked my hand.

Upgraded:

1-Had install dust purifiers. dust control standard under ten thousands level.

2-All models are using automatic stacking machine. Cancel hand making.

4, Encapsulation procudure(Cells seal packing)

Previous:

All made by hand.

Upgraded:

1-Had install dust purifiers. dust control standard under ten thousands level.

2-Add an automatic Encapsulation line.

3-Add 2 sets side and top seal automatic machine

5, Bake process

Previous: Used hand ventilator oven to brake

Upgraded: Using self-ventilating baking machines.

6, Liquid material injection process

Previous: Liquid material injected by hand.

Upgraded: Add 1 set automatic injection machine,improve work efficiency.

7, Battery kasei process(Charge & discharge recycle test).

Previous: Used common aging machine, need takes long time.

Upgraded: Using hot-pressing aging machine,to save aging time.

7, Exhaust sealing/Aging /Sub-capacity workshops are upgraded

Previous: Most processes are operated by hand.

Upgraded:

1-Added 2 sets automatic exhaust and sealing machines.

2-Add high tempreture aging workshop.

| Exhaust sealing workshop | High tempreture Aging workshop | Sub-capacity workshop |

C . Battery cell warehouse

Previous: Didn’t use fireproof door ,haven’t constant temperature equipment .

Upgraded : Every warehouses had installed fireproof doors and air conditioner .

D. Company photos

Enterprise entrance door

Front desk reception

Office area

External landscape

Office building

Production building

Dormitory building

Corporate culture promotion column

by Mario