Tel:+86 176 6535 6420

Copyright@ 2011-2018 Shenzhen Vigorpower Battery Co.,Ltd , All rights reserved. 粤ICP备2022022467号

Whatsapp/Wechat:+86 17665356420

TEL:+86755 2819 0804

Shenzhen Vigorpower Battery Co.,Ltd

Anhui Enrichpower Battery CO.,LTD

丨NEWS CENTER

Enrichpower Workshop Upgrade

Recently we made big changes to the workshop to reach international standard, to improve battery quality and production ability, details as below.

A.First floor upgraded <>

1,Production workshops

Imperfection: Positive and negative materials are put together, face a danger of cross-infection.

Upgraded: On the left of corridor are nagative produce precess workshops;one the right side are positive workshops. Every procedures are sperated.

Upgraded: Build a Air shower door at entrance, to aviod dust into workshop.

Upgraded: Add a first floor layout plan,to show wrokshops & procedures directly.

2, Materials Blending workshop upgraded

Previous:

1-No dust purifiers .

2-Nagative &positive materials are blending at same workshop.

Now:

1-Had install dust purifiers in workshops,dust control standard under thirty thousands level.

2-Nagative &positive materials blending are parted.

3-Windows gap had sealed,cann't open never.

Positive material blending workshop

Nagative materials blending workshop

3.Coating workshop upgraded

Previous:

1-No dust purifiers .

2-Nagative &positive materials are coating at same workshop.

Upgraded:

1-Had install dust purifiers in workshops,dust control standard under thirty thousands level.

2-Nagative &positive materials blending are parted.

Upgraded: Positive & nagative coating charging materials automatic.

Upgraded:

1,Positive materials coating workshop

2,Nagative materials coating workshop

4, Rolling compaction & Cutting workshop upgraded

Upgraded:

1-Had install dust purifiers.

2-Positive&nagative cutting workshop had parted

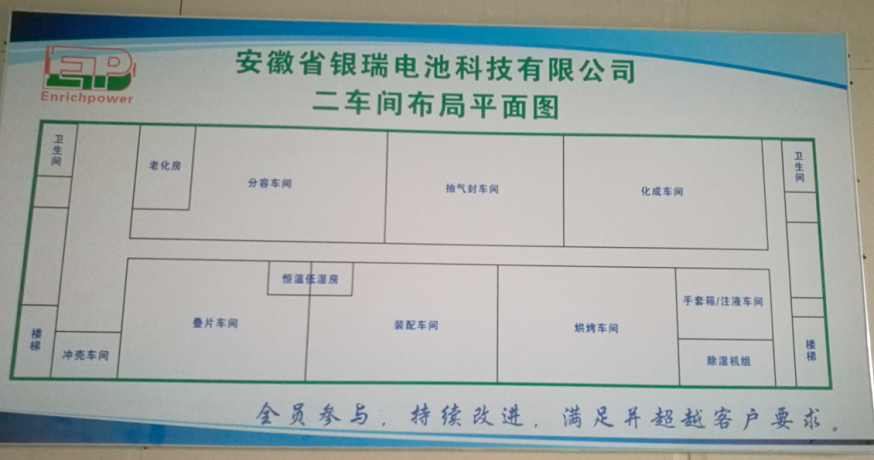

B.2nd floor workshops<>

1, Assembly & Quality test workshops

Previous:

Some workshops were didn’t seal ,result to temperture cannot be effectively controlled.

Upgraded:

1-Left of corridor are assembly workshops, right side are quality test workshops. Rational distribution to improve work efficiency.

2-All workshops are sealed.

2, 2nd floor layout plan

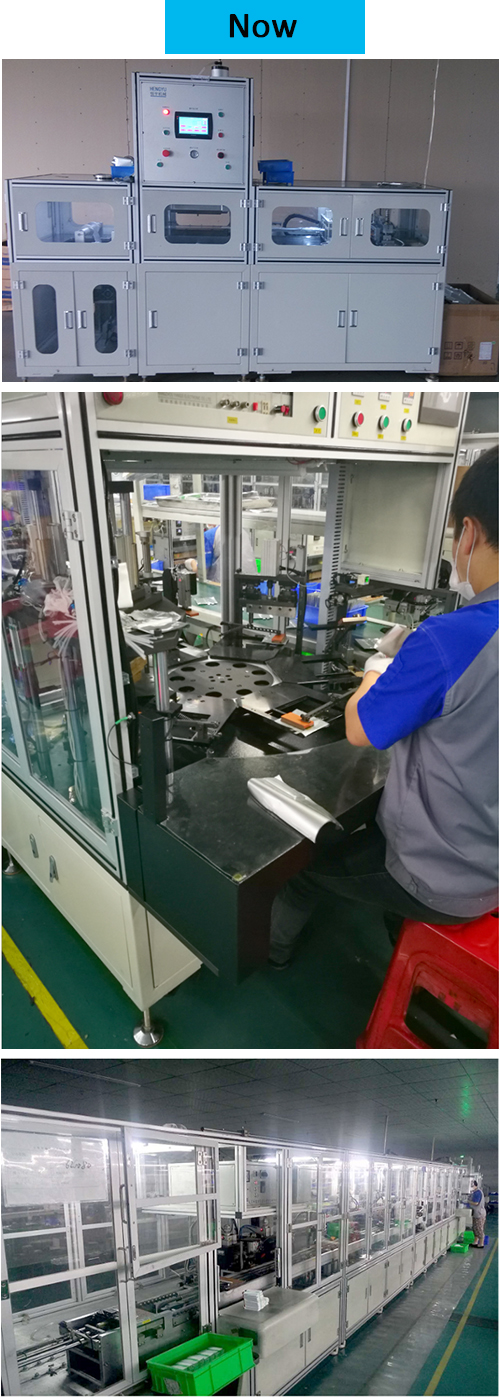

3, Stacking procedure

Previous:

1-No dust purifiers .

2-Some models Stacked my hand.

Upgraded:

1-Had install dust purifiers. dust control standard under ten thousands level.

2-All models are using automatic stacking machine. Cancel hand making.

4, Encapsulation procudure(Cells seal packing)

Previous:

All made by hand.

Upgraded:

1-Had install dust purifiers. dust control standard under ten thousands level.

2-Add an automatic Encapsulation line.

3-Add 2 sets side and top seal automatic machine

5, Bake process

Previous: Used hand ventilator oven to brake

Upgraded: Using self-ventilating baking machines.

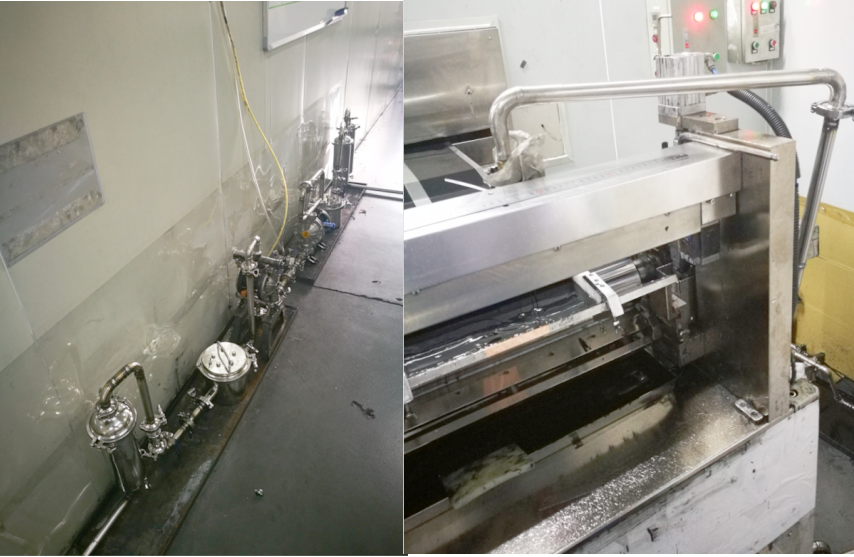

6, Liquid material injection process

Previous: Liquid material injected by hand.

Upgraded: Add 1 set automatic injection machine,improve work efficiency.

7, Battery kasei process(Charge & discharge recycle test).

Previous: Used common aging machine, need takes long time.

Upgraded: Using hot-pressing aging machine,to save aging time.

7, Exhaust sealing/Aging /Sub-capacity workshops are upgraded

Previous: Most processes are operated by hand.

Upgraded: 1-Added 2 sets automatic exhaust and sealing machines.

2-Add high tempreture aging workshop.

Exhaust sealing workshop

C . Battery cell warehouse

Previous: Didn’t use fireproof door ,haven’t constant temperature equipment .

Upgraded : Every warehouses had installed fireproof doors and air conditioner .

D. Company photos

Enterprise entrance door

Front desk reception

Office area

External landscape

Office building

Production building

Dormitory building

Corporate culture promotion column

by Mario